Heat exchangers

Products

Filter products

8 products found

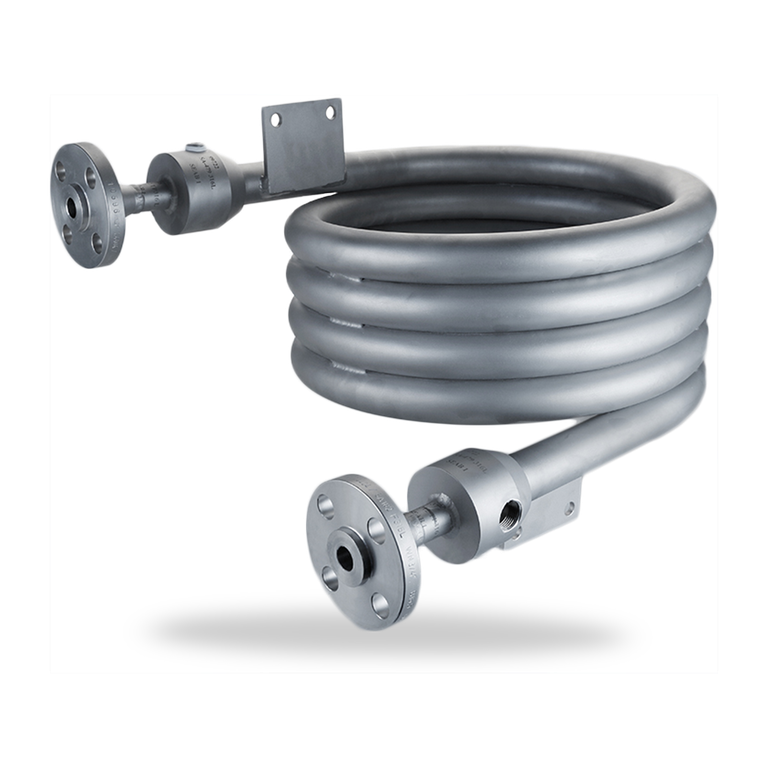

WDK

WDK5120 heat exchangers are used to cool process/barrier fluids in seal supply circuits. The heat exchanger has a wound double helix around the guide tube. Process/barrier medium in the tubes, cooling medium around the tubes.Circulation based on API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

WE6

Heat exchangers of the WE6 range are used to cool process/barrier fluids in seal supply circuits. WE heat exchangers are available in two standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell.For simple draining or venting of the cooling water side, the heat exchanger can also be supplied with ventilation/drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682).

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

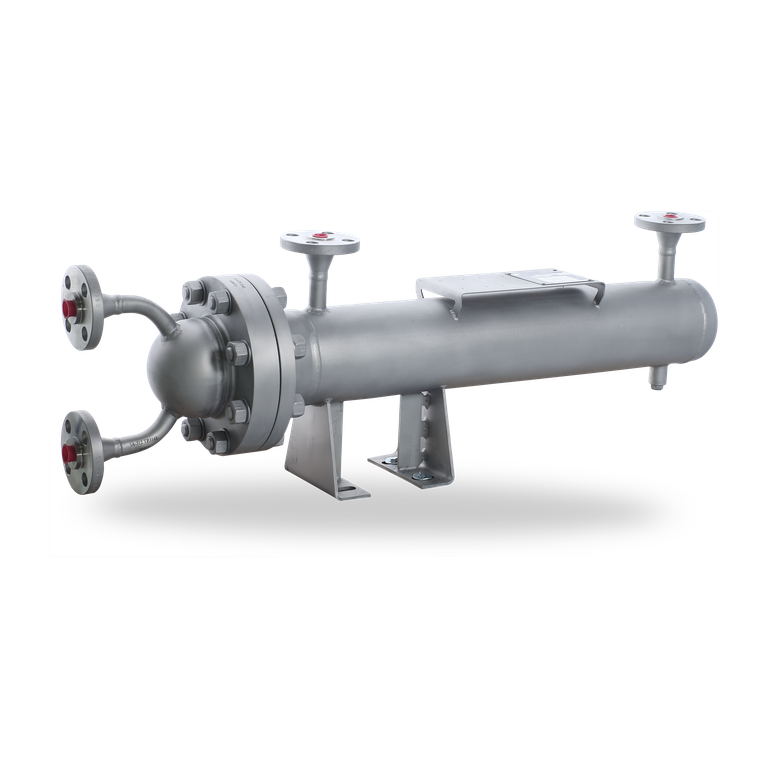

WED

Heat exchangers of the WED range are used to cool process/barrier fluids in seal supply circuits. Designed as a tubular heat exchanger with integrated guide plates, the process/barrier medium is directed through the shell of the WED and the cooling medium through the tubes.Circulation based on API 682 / ISO 21 049: Plan 21, Plan 22, Plan 23, Plan 41

WED5

Heat exchangers of the WED5 range (photo: WED5050/A020-D1) are used to cool process/barrier fluids in seal supply circuits. WED5 heat exchangers are available in 3 standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell. For simple draining of the cooling water side, the heat exchanger can also be supplied with drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to mechanical seal (optional in accordance with API 682).Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

WEL5

Heat exchangers of the WEL5 range (photo: WEL5200/M001-D0) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL5 heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. The integrated fan blower ensures the necessary cooling air flow. The WEL5 range is provided as a compact packaged unit completely assembled.Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

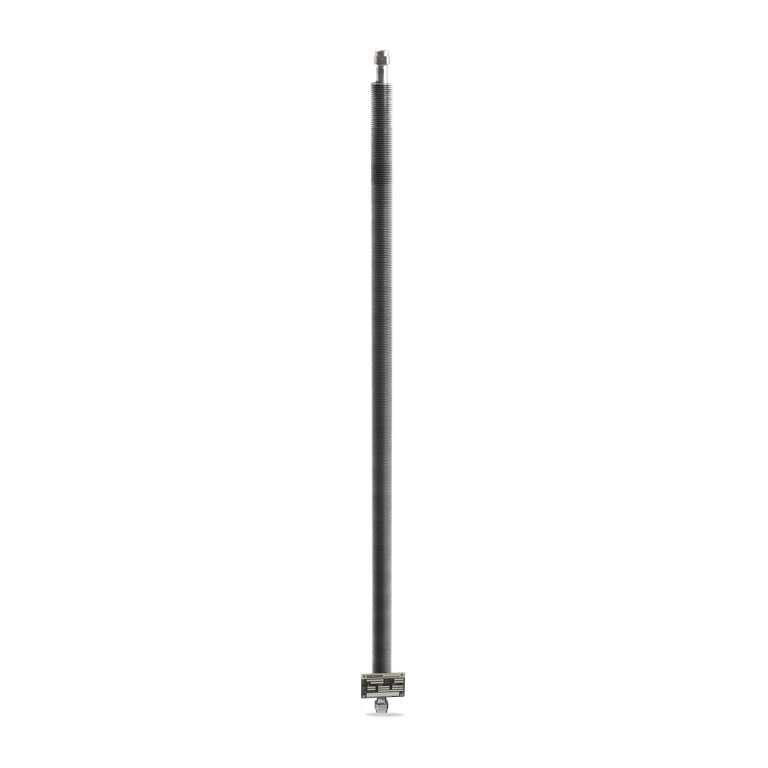

WEL1000

Heat exchangers of the WEL1000 range are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of straight, laser-welded finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. There is a choice of two different basic versions of the WEL1000 range (1 or 2 tubes), supplied fully assembled along with valves, base frame and other system components.Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

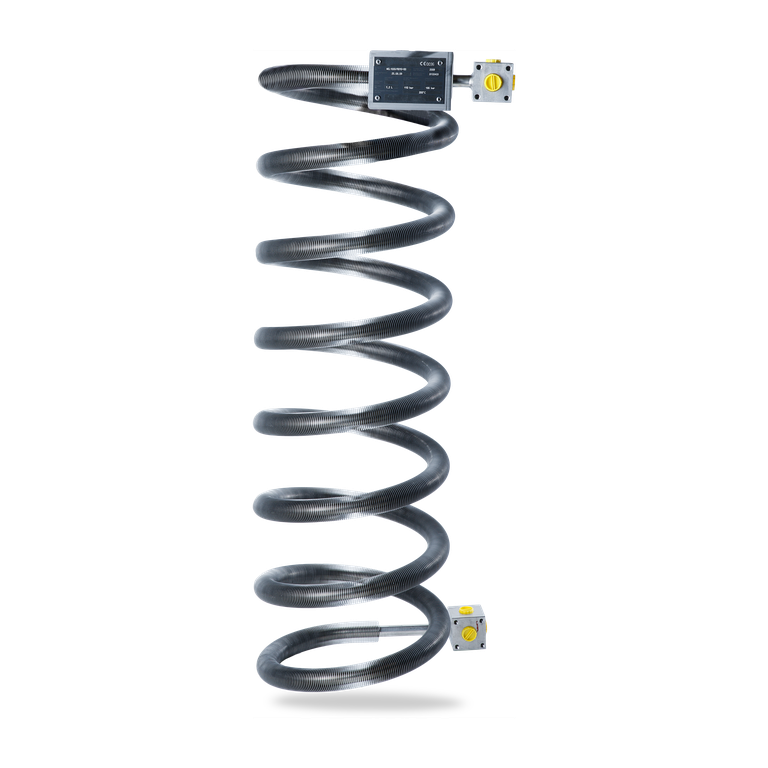

WEL2000

Heat exchangers of the WEL2000 range (shown: WEL2001/A040) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical, laser-welded finned tubes. The cooling medium is ambient air. There is a choice of three different basic versions of the WEL2000 range, supplied fully assembled along with valves, base frame and other system components.Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41